Projects 2010

Working on a PROJECT ?

Please pass it along.

Clickon

image to ENLARGE

December 25

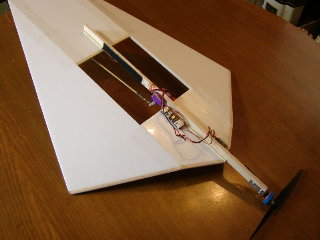

This is a LA-1 pattern ship from

the early 90's. I flew one then and it did very well for me. This is

the sister ship I never got around to building. They are about

impossible to find today and would probably bring a good price.

The plane is fiberglass fuse with foam cores and sheeting. Has

mechanical Supra retracts and uses an OS 61 long stroke with pipe. I

have put a new 2.4 system in it with all digital servos. When the

mechanics are finished will paint fuse and mono the wing/stab surfaces.

Mel Graham

|

Twin Ultra Update Mel

Graham (see Jan 14)

|

December

14

MY 1/4 SCALE CUB IS DONE. IT

HAS A SAITO 80 GK AND FUTABA ELECTRICS IN IT.

CHICK

|

December

13

December 8

|

|

Bonzo

UPDATE

As you can see.

it's done!!!!

I have to balance it, (and put on the Blue decals), then wait for the RAIN to stop !!

Marty

|

October 12

|

|

Bonzo is

coming along!! I did a weight and balance check ( CG ). And not

to bad. I will have to add weight to the tail, Install 3 servos in the

tail and place the battery at the trailing edge of the wing.. all

normal stuff..

I did weigh it when it was balanced and I am under my

estimated weight. It weighs 11 lb. I still think dry weight

will be 12 lb . With covering and cowl and can-o-pee mounts. The

muffler is 8oz so YEP 12 lbs. it will be.. Should be a rocket

with the Moki 1.8

Marty

|

October 7

Maiden flight of

SkySurfer

with GoPro

Well she flys with the camera aboard!

Now all I have to do is work on the pilot's flying skills.

Lennie

|

|

September

24

|

CUB

HERE IS A PIC OF

MY NEW BIRD ALL FRAMED UP.

60 SIZE CUB 90" WING SPAND SAITO 80 FOR POWER .

THE PEE WEE IS MY GRANDSON SETH .

CHICK.

|

September 23

BONZO

09-23-2010

As you can see I have been busy ( the

rain is good for something ). The can-o -pee is cut and detailed.

The cowling is cut and needs detailed. I have spent a lot of time

on little things like , cowl cheeks to wing faring top and bottom,

fitting the engine to the cowling and sanding sanding and sanding. (one

of my favorite things).

It has been an interesting build but it

is structurally complete. Now comes ALL the little things that has to

be done. I still have to make wing mount to fus and a mount for

the cap-o-pee and make some “ L “ brackets to install the cowling. None

of witch are difficult. Then start installing the control linkage

for elevators and rudder. The wing has to have ailerons cut in

and hinged and wires run for the servos (holes are already in the ribs

for this purpose). When I build the wing I did plan ahead and installed

servo mounts and the wing hold down hard wood. So just a matter

of remembering were they are!!.. (No I marked the plans )

The engine is inverted and the exhaust

will be the biggy. I would like to put a Pitts muffle on it but I

don't have the room front to back and a inverted side mount will be

cause to remove the left side of the cowling. Well that's not an

option ether.. So what now ?? Looking at the plain, one would say

the cowl cheeks are huge and they would be right, (all made to scale )

however, they are hollow inside and the cowl cheeks would be a good

place for a muffler. I'm guna have to design and build one, but

that is where it's guna live. It will be easier to make the

muffler if I don;t have to worry about muffler pressure, so I have

researched it and I will put on a Perry VP-30 pump on it. No

muffler pressure required.

A lot of you have asked when BONZO will

be done? Hell I don't know. It depends on the

weather. The more it rains the more I work on it. However I

do hope the flying season is not over yet!!!! So if you see rain

then you will see BONZO real soon. I'll keep you posted!!

Marty

|

September

20

September

8 - Well the rain has got me back on Bonzo. Here is the update and some

pics!! - Marty Wittman photos

September 3 - THIS IS _*MIKE'S*_ NEW PLANE I JUST

GOT DONE DOING! - CHICK FOSTER

July 28 - B787 about 80 percent finished. Some

painting needs to be done and the remaining electronics installed.

Check out the special multi blade fan! Mark Cross

July 16 - (See June 21 and June 14) -

The wings are Kevlar which is the yellow portion for flexible strength

and the black is carbon fibre over kevlar where the landing gear is for

high strength. The rest is fiberglass. I will be painting soon - Marc

Cross

June 27 - WELL SHES ALMOST READY TO HAVE HER MAIDEN

FLITE JUST A FEW THINGS LEFT TO DO. - CHICK

June 21 - EDF B787 that I just finished with the

epoxy and fiberglassing and painting of the fuselage. - Mark Cross

June 14 - I have a Boeing 787 ducted fan aircraft I

am putting togetherit uses twin 70mm EDFs 70 in span and is fiberglass

over foam with carbon fiber for stress areas. Landing gear is

machind aluminum with functioning oleos. The model is licensed by

Boeing that comes from a company in Kent Whashington. If I have the

time I would like to have ready for flight before September. I still

have to install the flight servos and finish and paint in Boeing

colors. Steering servo is installed andfuselage is completed. More to

come - Mark Cross email mchartmann@yahoo.com

May 10

- This is a scaled up version of the stringless wonder that was in the

latest AMA magazine.

Have not test flown it yet. Weight 6.5 Oz. Span 18" Length

30".

Rich . - Rich Richardson photos

April 29

-

Here are a couple pics of the plane I'am building, SIG Citabra. all

framed up. I'am putting a 61 Magnum in it. - Chick Foster photos

Feb 17 -

Here are a couple pics of my winter project, a scratch built Shoestring

Racer. - Chick Foster photos

Feb16

- Marty Wittman photos

|

|

|

|

Bonzo

UPDATE

The fus is together, the wing is

built. I have to add the tips and cut the ailerons in. When I was

building the wing I also installed the servo mounts after sheeting one

side. Witch takes some planning. Well, not enough planning on my

part because when I went to sheet the other side. The servo

mounts were on the wrong side!!.. I don't like the servos on the

top of the wings !! ( GRIN) Oh well. No matter how long you

been building ,you still make mistakes!!!...

OK. On to the fun stuff.. I am

finding out that the plain has to be built all at one time and all in

one piece. You say,, How can that be??? Well sense the

planes are for a U-Control of a very small size (28in wing) and the

wing is glued to the fus and then the tail is glued and then you build

the turtle deck and canopy and then build and install the cowl cheeks (

The cowl cheeks also hold down the front of the wing) and then build

the front deck along with the cowling ( top and bottom) making the

plane a one piece airplane. All of witch are built over the wing. Geee

, That would be easy to do, But this wing in 62in and has to come off

,however, It still has to be built in one piece.

I do have most of the pieces cut out

and fitted. I just haven't figured out yet how this is guna work

? I fit all the pieces on the fus ( you got to love pins) ,stand

back and look. Then try to figure out were to start? I

think I will start with the horizontal and the vertical and build

forward. That would be ,Tail feathers, turtle deck, canopy, front deck

and cowl cheeks and cowling. In that order. Well, I'm not ready for

that yet!!!! I can't get the wing off with the cowl cheeks on so

I got some head scratching to do there !!!! I may have to redesign the

front wing mounts !!! Anybody starting to think ARF ,yet??

The one big problem I am having now

is what engine do I put in this thing? I have a Sato 91 that I thought

would work but as I build and see how big Bonzo is going to be I don't

think the 91 will do it!!!.So that brings up other problems. Like

firewall to back plate distance. Do I move the firewall back or do I

make the cowling longer!! I have measured that distance on my other

planes that have gas engines and it varies from 5 ½ to 6

½ inch. Bonzo's plans from firewall to back plate in only

4 1/2inch.

<> Yep!!! One of many problem of scratch

building. Weight and balance has to figure in here also. I am

beginning to see why there are less and less scratch builders out here.

However I do enjoy what it take to get one of these in the air.

To Be Continued..... Marty

Wittman

Bonzo

Update....02-16-2010

|

Jan 19

- Marty Wittman photos

|

|

|

|

Bonzo

is on the boards!!!!!

It must be raining! I got the itch to start working on Bonzo so

off to the man cave!!!!!

When you only have a set of plans and no kit to

start to build you have to start someplace. So the first thing

you do is cut out all the parts you will need for the kit out of paper

(that's why you make a copy of you original

planes) then you have to transfer the paper cut outs to the woodso you

can cut them out to make a kit to build !! You have

to really , really like building.

All the pieces are cut for the fus and the fus sides

and doubler are cut and glued together. No I haven't put the fus

together yet. How ever, the wing saddle did take some time to draw out

and then cut the wing saddle into the fus. You see the wing

saddle has to be 100% right!!!!! My problem is that I am only a

99 % guy so it took me a lot longer to get it to 100% ! The

wing on any airplane is the basses for all other setup to the plane.

The stabilizer is set to the wing. In the case of Bonzo it is a 0 % -

0% incidence The wing is also centered on the thrust line

as is the stab and engine. So the wing has to be at 100 % It took

a lot of measuring and more measuring and checking and rechecking but

after a bit ,, you say OK cut it, right or wrong!! I did

and we will see how it goes..

The wing is pretty straight forward. I

thought. If I could build the wing to the plans it would be, but, and

this is a big but!! The original plans are for a U-Control plane

with a 28inch wing that has the wing glued to the fus. along with the

canopy to make a one piece airplane. Well,now that I have the

wing up to 68inch and it's guna be an R/C plane there is a lot of

redesigning to do. Besides, I don't have a truck that big to

carry it in one piece. So the only thing I can say about the wing is.

It is in the design stage!!

Lets see, The only thing I have to do is..build the

wing/ Mount it to the fus,/ build the turtle deck and canopy

along with the front top and then CUT THE FUS to get the canopy off so

I can take the wing off and then design a mounting system to put it all

back together.. WHY?? WHY ?? WHY?? didn't someone talk me it

building an ARF of some kind, any kind!!!!

Oh Well

More to follow!!!

Marty Wittman

Jan.

12 2010

|

Jan 14

- Mel Graham photos

|

It started as a

Ultra Sport 60 kit

I have modified it to a

twin with two OS 46 AX's. The fuse has a new nose and I modified the

tail surfaces to

provide more area. It has retracts (tri) and the wing is fully

sheeted. I added glass cloth with water base poly urathane.

About six coats of poly, final two had

talc added for a filler.

The pictures do not show the latest stage. It has two coats

of auto Advantage urthane primer sprayed on and then heavily sanded

with 200

400 paper dry. Need to spray another coat of primer

and sand to see if

surface is ready for color coats. At this stage the finish has added

about 3 oz

to the structure.

Has a bit of clean up

work to go, but is getting close to color coats. I

probably will use something different this

time like maybe WHITE, RED, and BLACK. Hmm.

Ann says I am a "touch"

predictable??

Mel Graham

|

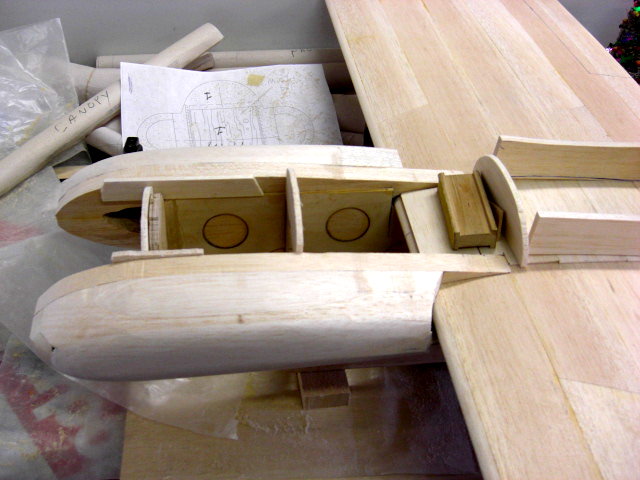

Jan 12 - Mickey

Cohen photos

Sig 1/4

scale clipped wing Cub

Here are some

pictures of my winter building

project. It is a . The

wingspand is 86 inches and I expect it to weigh in at 15 pounds. The

power

comes from an OS Gemini 160. The landing gear is a functioning bungee

gear. Mickey Cohen

|

Jan 11 - Kenton Melville photos

|

Nexstar

Here's the stuff I did to my Nexstar in Nov

'09. A few of the guys have seen it out at the field a few times in

December. I

have 27 flights sofar, it's very stable. Just waiting for more sun.

<>Feel free to link a picture

for others to see where/what this

link represents.

Kenton Melville |

|

|